Digital technology is profoundly transforming industry. Automation, real-time data collection, and equipment connectivity have ushered in a new era: Industry 4.0.

At the heart of this revolution, MES software (Manufacturing Execution System), also called production management or control software, plays a crucial role in the digitalization of factories.

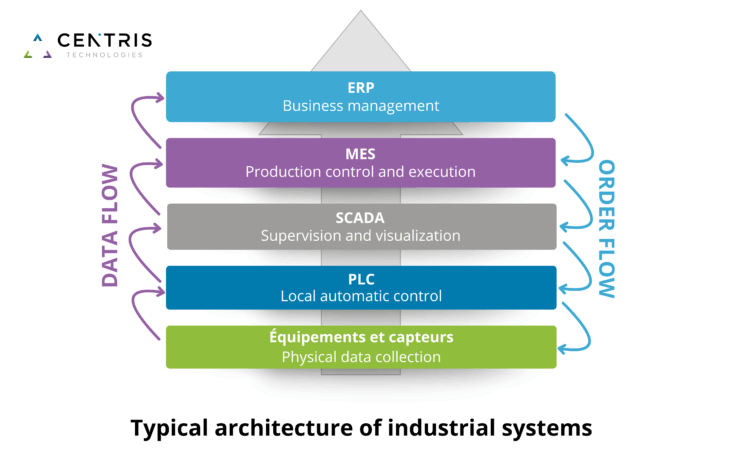

A true digital link between the management system (ERP), the supervisory system (SCADA), and the production floor, MES ensures smooth information flow, traceability of operations, and process optimization on the factory floor.

In other words, it is the digital conductor of your connected factory.

- What is MES software?

- How does MES software work?

- What are the benefits of MES software?

- How to choose your MES software and integrator?

- Which industrial sectors benefit most from MES?

- Why use MES software for industrial growth?

- Interoperability: a key factor for MES success

- Boost your industrial business growth by integrating MES software

What is MES software?

MES software coordinates, supervises, and optimizes production execution in a factory. It also collects and centralizes production data in real time. Essentially, it ensures coordination between production requirements (often coming from the ERP) and the execution of manufacturing orders.

Data handled can include traceability, quality, scheduling, and maintenance. This information helps optimize production and reduce downtime.

For implementation and operation, the expertise of an MES software engineer is often essential. Centris Technologies teams can support you throughout this process.

How does MES software work?

MES software manages production. It collects real-time data from machines, operators, and other systems on your production floor (PLCs and SCADA). It centralizes and analyzes this information to monitor, control, and optimize manufacturing operations.

MES is a key element of full vertical integration for managing a production floor (sometimes called CIM, or Computer Integrated Manufacturing), which aims to connect all enterprise systems, from order entry (ERP) to real-time production control (SCADA). Its main functionalities include:

- Manufacturing order management: scheduling, progress tracking

- Real-time production monitoring: live supervision, anomaly detection

- Quality and traceability: batch control, compliance

- Performance analysis (KPIs): overall equipment effectiveness, productivity

By collecting all this information, MES enables precise tracking of production and quick identification of potential issues. Production management is also aligned with business needs thanks to ERP-MES integration, which allows management of inventory, customers, orders, and more.

What are the benefits of MES software?

Real-time production tracking through MES offers numerous advantages for industrial companies:

- Optimized productivity and reduced costs: collected data allows for efficient production organization

- Improved visibility of the production line: the software connects to machines and operators for real-time insights

- Traceability and regulatory compliance: crucial in sectors like food, pharmaceuticals, and aerospace

- Improved quality and reduced waste: automation reduces the risk of human error

These aspects have a major impact on overall industrial performance. Integrating MES is a significant asset for industrial competitiveness.

How to choose your MES software and integrator?

The MES software market is full of options, each with its strengths and specializations. Finding the right one for your needs can quickly become complex. Often, it is recommended to select the integrator first, who will guide you through the project.

MES projects are long-term: the quality of the relationship and team compatibility greatly influences project success. A good integrator will help you select the software best suited to your needs, and often, a strong team can achieve excellent integration even with a less advanced tool, whereas a great tool poorly integrated won’t deliver expected results.

Tips for choosing an integrator:

- Evaluate the company’s experience: request case studies and references showing expertise with various MES software

- Examine project methodology: transparency regarding timelines, budgets, and communication is essential

- Check certifications and official partnerships held by the firm

- Ask about post-project support: a good integrator should support your teams after implementation

- Ensure a good working relationship: collaboration should be smooth and enjoyable, as you’ll work together for months or years

Once the integrator is selected, technical parameters for software selection can be specified:

- Verify your IT infrastructure can support MES software

- Identify equipment and systems to connect to MES

- Determine data to collect and analyze based on operational objectives

- Ensure technical prerequisites are in place, including PLCs and connected machines; if not, the integrator can help implement missing elements

Choosing the right software and integrator directly impacts project success. To maximize ROI, it is essential to design a long-term automation strategy, clearly defining performance and data objectives. This approach ensures the right tools are implemented at the right time, creating a sustainable and scalable digital ecosystem.

Which industrial sectors benefit most from MES?

MES software benefits all industrial companies, but certain sectors with specific requirements gain the most:

The manufacturing sector: on complex assembly lines, centralizing data through a MES is a significant advantage. This is especially true for the electronics and automotive industries, but it applies broadly across the entire manufacturing sector.

The food industry: this sector faces strict traceability requirements. Implementing a MES facilitates this process by enabling batch control.

The chemical and pharmaceutical sector: another industry that must ensure product compliance and validation. MES proves to be a valuable asset in these situations.

The aerospace and energy sector: this industry faces critical safety challenges. MES helps ensure the security of both data and operations.

MES software can therefore be particularly advantageous in industrial sectors that require enhanced control and monitoring. It is essential for any company looking to take the leap toward Industry 4.0.

Why use MES software for industrial growth?

Integrating MES software can drive growth in your industrial company. By improving production efficiency, it provides a competitive edge and helps maintain competitiveness.

It is also a key step in digital factory transformation, enabling greater automation. With data collected and generated by MES, decision-making and strategic business direction improve.

MES integration is not just performance improvement; it is a true profitability lever. By reducing downtime, optimizing resources, and decreasing waste, MES delivers tangible ROI within months.

Many companies report increased productivity, reduced material losses, and better utilization of industrial assets. Using precise performance indicators, MES gives managers a quantified and strategic view of factory performance.

Interoperability: a key factor for MES success

MES software integrates into a complex environment composed of ERP, SCADA, PLCs, and sometimes IIoT solutions. Interoperability with these tools is essential to ensure smooth data flow and prevent information silos.

Modern MES software can communicate with a wide variety of protocols and industrial equipment, facilitating integration in heterogeneous environments.

This interoperability provides a unified view of production, better coordination between departments (planning, maintenance, quality, production), and reduced data transfer errors.

Boost the Growth of Your Industrial Business by Integrating MES Software

MES software is a valuable asset for companies looking to advance in the process of industrial automation. By analyzing collected data in real time, it helps optimize manufacturing operations for increased productivity and reduced waste.

In today’s era of Industry 4.0 and smart factories, integrating PLC, SCADA, MES, and ERP systems allows you to stay competitive and gain a decisive edge over your rivals.

To choose the solutions that best fit your needs and configure them accordingly, trust the experts at Centris Technologies. With our extensive experience in industrial automation, we are a key partner to guide you through this major digital transition.