Industrial Softwares

Optimize your manufacturing production with our SCADA and MES industrial production management software

Centris Technologies develops customized production management software to optimize your manufacturing operations. Our industrial solutions integrate real-time supervision, machine downtime reduction, and productivity improvement for your production lines.

SCADA Industrial Supervision

Custom MES solutions

ERP-MES-SCADA Systems Integration

Manufacturing solutions connected to ERP

Industrial software solutions are generally based on two major product families: SCADA (Supervisory Control And Data Acquisition) and MES (Manufacturing Execution Systems).

Our systems integration expertise allows you to efficiently connect your industrial equipment to your ERP system. We specialize in developing MES/SCADA solutions and ERP connectivity.

Centris Technologies has extensive experience in creating open industrial software solutions built on commercially available platforms such as PcVue, Ignition and COOX, and others.

The benefits of connected industrial data

- Real-time supervision of production lines, machines and industrial processes;

- Production flow optimization with complete traceability and performance indicators;

- Minimization of unplanned downtime and optimization of industrial resources;

- Production execution management of batches and work orders;

- Equipment interconnection;

- lerts and notifications, trends and historical data;

- Performance reports, traceability, web portals;

- Mobility and contextual data;

- Large screens, OEE, KPIs and other 'real-time' production data;

- Bidirectional communication bridge with ERP.

The benefits of Centris Technologies software solutions

Our offering is comprehensive, but every project starts with the same priority: thoroughly understanding your needs.

It’s not about following ‘digital transformation’ trends at all costs, but about precisely identifying your challenges: what are your pain points, your needs, your opportunities? And most importantly, which solutions will have a real impact for you?

Our approach is built around three key pillars:

- Technological integration: Data unification and connectivity between all your systems;

- Specialized support: Dedicated expert team and technical support;

- Scalability: Manufacturing IT systems that grow with your business.

Discover the possibilities and opportunities for managing your plant

Our team of systems integration experts supports you in the digital transformation of your plant. Book your free consultation to discover how our solutions can reduce your operational costs and improve your manufacturing productivity.

Case Studies

Specific needs, deep integration of Centris Technologies solutions within critical operations in large-scale enterprises.

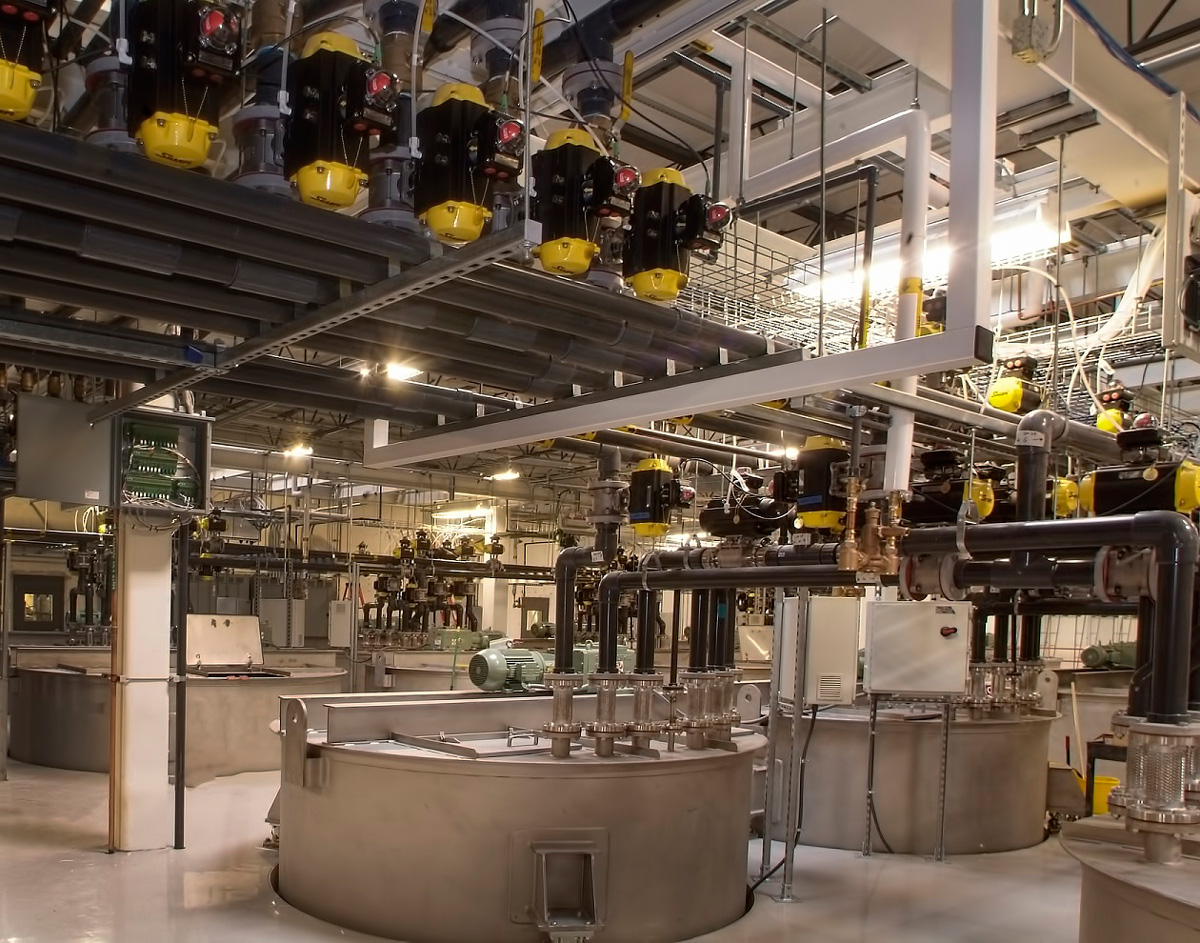

Production process supervision and management

Phoenix (AZ), États-Unis

As part of building a new plant that consolidates the entire production of two former facilities, the client needed an integrated real-time control solution coupled with production operations management functions with ERP integration.

The client had set itself the mandate of having the most modern plant in the world in this regard.

An evolving and constantly changing system

Centris Technologies developed a SCADA/MES system that covers the entire production operations of the plant. The system manages over 125 tanks and reactors and executes more than 30 recipes per day.

For 10 years, following the system startup, Dunn Edwards has implemented nearly 2,000 hours of continuous improvements annually, so that the system evolves at the same pace as the client’s needs.

And the benefits?

Before the automation of the new plant, the client dealt with a “first pass yield” of 40%. 6 out of 10 batches had to undergo some form of rework to meet the strict quality requirements.

Now, less than 5% of batches need to be reworked. The savings per gallon produced are unequivocal – they produce much more high-quality product for much less cost.

The system deployed by Centris Technologies, as well as the plant, have won numerous innovation and operational excellence awards.

SCADA and ERP (SAP) Integration

Longueuil (QC), Canada

During the development and integration of new automated production lines at the Longueuil plant, the main integrator needed expertise to integrate the SCADA that controls all line activities with the company’s SAP ERP software.

Massive data integration

Centris Technologies developed a dedicated “communication bridge” software for this task by linking the SCADA with SAP via OPC XML using the PI/XI layer.

The communication bridge was developed adopting a “product” philosophy – essentially, to allow P&W to be 100% autonomous with the software usage.

What's next?

The client has been operating the software solution autonomously for several years with very few support calls to Centris Technologies.

The massive data generated by the production lines is all fed back to SAP for historization according to FAA standards.