Totally integrated industrial automation

Specialized in industrial automation support, Centris Technologies transforms your operations through innovative automation solutions.

Programmable logic controllers and PLC and soft-PLC solutions

Benefit from our PLC programming expertise with leading industrial brands.

Beckhoff

Siemens

Allen-Bradley

Omron

Wago

Automation integration solutions

Our comprehensive solutions connect your equipment to your enterprise infrastructure via SCADA-MES-ERP connectivity. This process automation approach ensures seamless communication between all your machines and enterprise systems.

- Control system design, physical and software architecture;

- Advanced multi-platform PLC programming;

- SCADA systems and process supervision;

- Preventive maintenance and technical support;

- Training your teams on new technologies.

The benefits of industrial process automation

Precisely control your industrial processes;

Monitor your operations 24/7;

Manage the operating modes of your equipment;

Execute automated sequences;

Collect real-time data and manage critical parameters of your processes, machines, sensors, and auxiliary equipment;

Reassign your resources to value-added tasks by automating repetitive tasks;

Reduce downtime of your production lines.

Manufacturers facing resource challenges

Employees are key resources in the manufacturing world. Certain repetitive production processes can be automated to allow you to reassign your resources to more complex and rewarding tasks.

Centris Technologies, with its mechanical and vision partners, is able to provide modern automation solutions that are easily integrated into your production processes.

Our industrial automation support covers all phases of your project.

Our range of solutions is extensive but always starts with the same step: thoroughly understanding and identifying your needs. It’s not about following a trend or implementing all the concepts promoted by ‘digital transformation’ but rather identifying what your pain points are, what your needs are, what your opportunities are, and which solutions will truly bring you added value.

Ready to automate your industrial processes?

Our specialists in industrial controllers and automation solutions support you in your digital transformation.

Case studies

Specific needs, deep integration of Centris Technologies solutions within critical operations in large-scale enterprises.

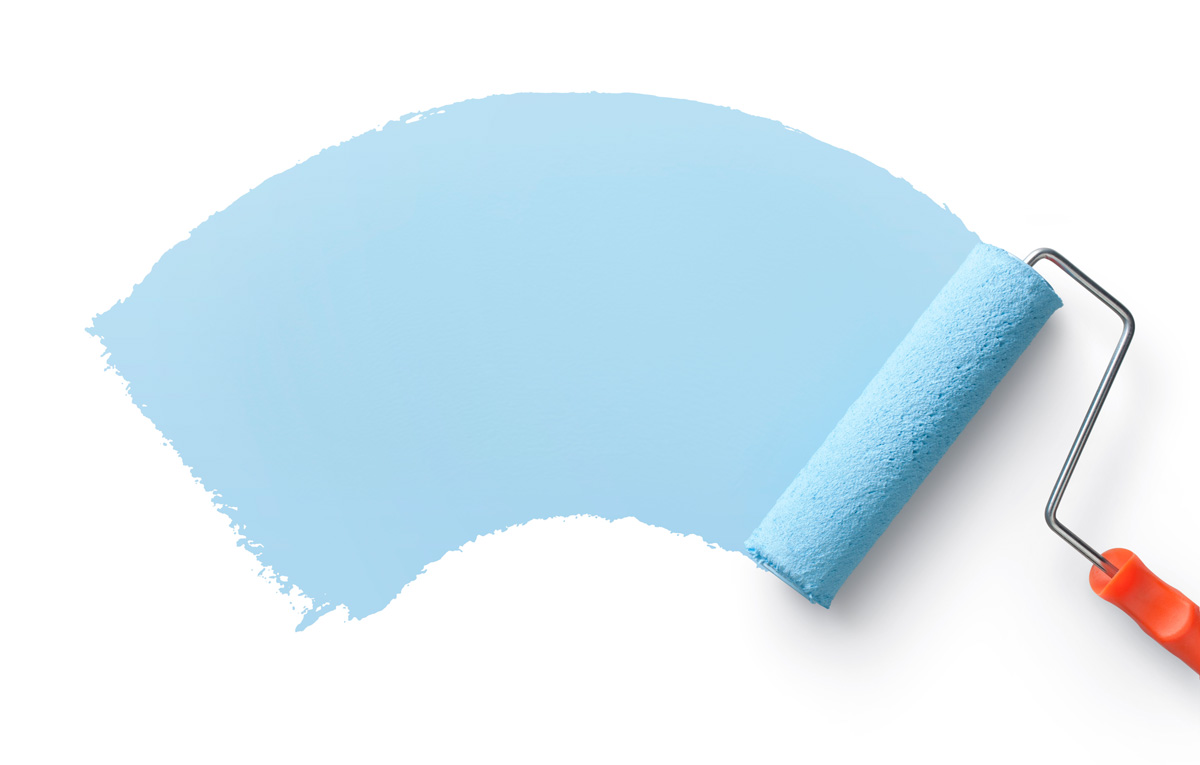

Production process automation and management

Burford (ON), Canada

Home Hardware, Beauti-Tone Paints product division, has operated a paint and household products manufacturing plant since the 1980s.

The automated controls of this plant had reached the end of their useful life and were no longer supported by the manufacturer or the original integrator.

An evolving and constantly changing system

Centris Technologies developed a control and SCADA/MES system that covers the entire production operations of the plant. The system manages over 80 tanks and reactors and executes more than 15 recipes per day. Additionally, 12 filling lines totaling approximately 50 machines have been integrated into the SCADA system to enable their supervision.

And the benefits?

Before the complete overhaul of the automated control systems, the client was no longer able to implement improvements within the system and there was room for performance improvement on the filling lines.

The new system is scalable, connected to the client’s ERP, and has enabled a 30% reduction in time dedicated to the important filling activities of products manufactured at the plant.

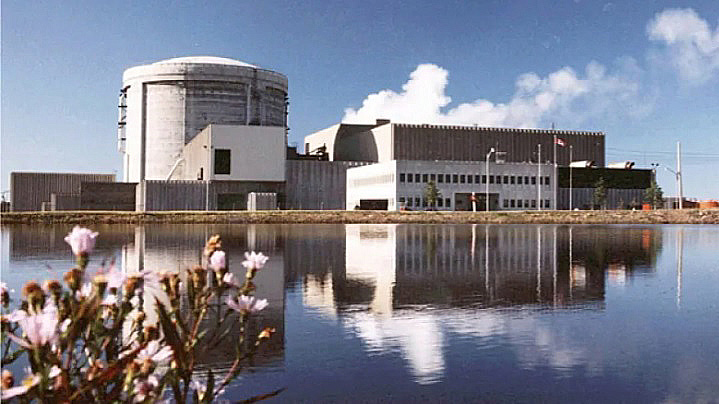

Secure and redundant control architecture

Drummondville (QC), Canada

Wajax Power Systems was commissioned to supply a set of emergency generators for the Point Lepreau nuclear station in New Brunswick.

As part of this project, the controls for the generators, as well as for the building housing them, had to be redundant and SIL certified

Highly regulated environment

Centris Technologies developed the architecture based on Rockwell Automation ControlLogix brand programmable logic controllers.

Centris Technologies also took into account the strict standards of the nuclear industry, given that the documentation and validation of this system were also part of the deliverable. Furthermore, due to the project’s complexity and the number of stakeholders involved, Centris Technologies was awarded the overall project management contract.

And the result?

The system, fully validated and in line with applicable standards, has been in operation for nearly 8 years.

These generators, the third pair of emergency power supply for the plant, now provide electricity to operate the reactor cooling pumps in case of natural disaster or loss of main electrical grid power.