In the era of Industry 4.0, companies must rely on automation to remain competitive. Among the key technologies driving this digital transformation, SCADA systems (Supervisory Control and Data Acquisition) play a central role.

These solutions enable real-time monitoring, data collection, and analysis on the production floor. They have become indispensable across many industrial sectors, manufacturing, chemical, agri-food, and more, to optimize operations and reduce downtime.

But what exactly is a SCADA system, how does it work, and what benefits can it bring to your plant? That’s what we’ll explore in this article.

-

- SCADA: Definition of Supervisory Control and Data Acquisition

- SCADA Architecture: Components and Operation

- SCADA and PLCs (Programmable Logic Controllers): An Essential Duo

- Key Features of a SCADA System

- SCADA: A Partner for Better Energy Performance in Your Business

- Why Implement SCADA in Your Plant?

- How to Choose the Right SCADA System for Your Industry?

- Ready to Integrate SCADA into Your Plant?

SCADA: Definition of Supervisory Control and Data Acquisition

The acronym SCADA stands for Supervisory Control and Data Acquisition.

It is a supervisory system that combines hardware and software components to collect real-time data from production lines, with the goal of monitoring and controlling industrial operations.

The objective? Increase responsiveness to problems and minimize slowdowns and downtime at every stage of production, thanks to precise equipment control and data-driven decision-making.

SCADA Architecture: Components and Operation

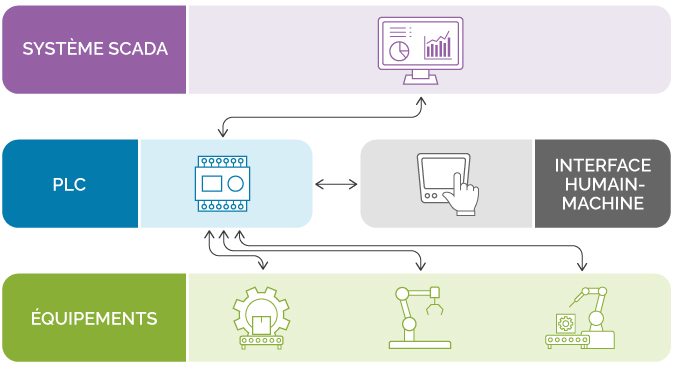

A SCADA system is the combination of hardware components and computer software that communicate together to collect data and control industrial operations.

- Sensors and actuators are installed directly on equipment and production sites to gather data.

- Programmable Logic Controllers (PLC / API) are electronic systems that control machines on industrial production lines.

- Remote I/O modules are electronic devices that extend the communication capabilities of a PLC or control system, allowing it to connect sensors and actuators located remotely.

- Human-Machine Interface (HMI) is the operator screen that allows people to interact with equipment in a specific area of the plant, such as a single machine.

- Supervisory system (SCADA server) collects, analyzes, and displays data in real time, allowing control of the entire industrial process.

With this architecture, companies gain a powerful tool to monitor, adjust, and optimize their industrial processes in real time, thereby improving overall performance.

SCADA and PLCs (Programmable Logic Controllers): An Essential Duo

Programmable Logic Controllers (PLCs), also known as API in French, are essential components of a SCADA system. These electronic devices, comparable to small computers, control equipment on the production floor. They execute commands sent from the SCADA server and help collect real-time data by transmitting it back to the server. PLCs and SCADA communicate through an appropriate communication protocol configured during system implementation.

SCADA architecture diagram with sensors, PLC, HMI, and supervisory server.

Main Features of a SCADA System

Industrial automation makes it possible to collect a wide variety of data and control many aspects of operations with the goal of optimizing processes and improving overall productivity. In particular, SCADA systems enable:

- Real-time monitoring of operations

- Data historization to review and compare performance over specific periods

- Alarm and alert creation to improve responsiveness in case of issues on the production floor

- Remote control for greater centralization and optimization of processes

- Dashboard and performance report (KPI) creation for precise results tracking

SCADA: A Key Ally for Better Energy Performance in Your Business

In the industrial sector, energy efficiency is a very important factor that can be optimized in many ways. By implementing a SCADA system, you can improve your company’s energy efficiency and achieve substantial savings. Here are a few ways SCADA can help:

- Real-time data monitoring: track parameters of your energy consumption such as power, voltage, and current over different periods. This allows you to identify potential optimizations for better energy allocation.

- Remote control: start up or shut down equipment remotely to avoid wasting energy when machines are not in use. Remote control also helps optimize operations, reduce waste, and generate energy savings.

- Problem detection: SCADA enables you to spot problems and anomalies in your plant, helping optimize production processes and reduce energy waste.

- Decision-making: SCADA allows you to test different production processes, compare their energy consumption, and choose the most efficient one.

SCADA is therefore a powerful tool to achieve quick energy efficiency gains. It can also be used in combination with other tools such as an Enterprise Resource Planning (ERP) system or an Energy Management System (EMS) for even greater energy optimization. Improved energy efficiency not only generates cost savings but also contributes to reducing your environmental footprint.

Why Implement SCADA in Your Plant?

The implementation of a SCADA system in a plant offers numerous advantages:

- Productivity and operational efficiency: with real-time monitoring, you can optimize production processes, reduce downtime, and minimize human errors.

- Failure prevention and predictive maintenance: data helps monitor equipment condition and take preventive action before breakdowns occur.

- Integration with ERP, MES, IoT: SCADA integrates seamlessly with other systems such as ERP, MES, or Industrial IoT (IIoT), creating a cohesive, agile, and highly optimized production ecosystem.

- Cloud accessibility: if your SCADA system is deployed in the cloud, you benefit from enhanced accessibility for easier data monitoring.

How to Choose the Right SCADA System for Your Industry?

There are many SCADA solutions on the market. To select the one best suited to your business, several criteria must be considered:

- Project size: how much data do you want to collect? How many machines are involved?

- Compatibility: which software is most compatible with your equipment’s communication protocols? Is it also compatible with your other systems (ERP, MES, etc.)?

- Security: are data records secure? Are communications with equipment properly protected?

- User experience: is the software user-friendly?

- Total Cost of Ownership (TCO): which solution best fits your budget?

To guide you in this choice and especially for the implementation of the software, it’s essential to work with specialized integrators. The benefits of a SCADA system will be maximized when the integration is tailored and well adjusted to your needs. SCADA integrators understand your challenges and can propose the most suitable solution.

At Centris Technologies, we have over 20 years of experience in SCADA integration and industrial automation. Our expertise is recognized internationally, with clients across North America.

Our SCADA certifications include:

We also work with the following technologies:

Choosing the right SCADA solution for your industrial needs is essential. To make an informed decision and ensure a successful implementation, rely on the expertise of a qualified SCADA integrator.

Ready to Integrate SCADA in Your Plant?

Adopting a SCADA system is a major step forward in the digital transformation of industries of all kinds (food & beverage, chemical, manufacturing, etc.). It is the ideal solution for companies that want to:

- Achieve substantial productivity gains

- Optimize their production processes

- Improve their energy efficiency

- Reduce losses and downtime in their plants

- Gain precise and responsive monitoring of their operations

Are you ready to embrace Industry 4.0? Discover how our team can integrate a high-performance SCADA system designed to optimize your industrial processes, improve your energy efficiency, and strengthen your competitiveness.

Contact our SCADA integration experts today to optimize your industrial processes and boost operational efficiency.