The results of the 2018 Quebec Industrial Barometer unveiled

We were at the presentation of the results of the 9th edition of STIQ’s Quebec Industrial Barometer. The study demonstrates more than ever that innovation

They trust us

Centris Technologies offers its customers the opportunity to establish an ongoing partnership to support, maintain and evolve their software and automation systems.

We can become somewhat of an extension of your Internet technology team or your full support team if you don’t have the necessary internal resources, or just the desire to manage such a team.

The PRP or Permanent Resource Plan assures you that we will always keep trained employees on your systems so that we can intervene quickly in case of problems.

In addition, we also include software updates and continuous improvements to your system, depending on the needs of your operations or the market in which you operate.

These plans are completely customized for you.

We can help you optimize the control applications of your equipment and build software solutions to monitor and acquire data from your various process steps.

Recipe management, quality control, data traceability and productivity and waste monitoring, in an automated and computerised context, are key benefits for any food or beverage producer.

Formula management, control accuracy, process stability and traceability are essential elements for optimized productivity.

Development of embedded software within your equipment as well as application backends to maximize the user experience of your customers. Quality and reliability are key issues.

Specific needs, deep integration of Centris solutions into critical operations in large companies.

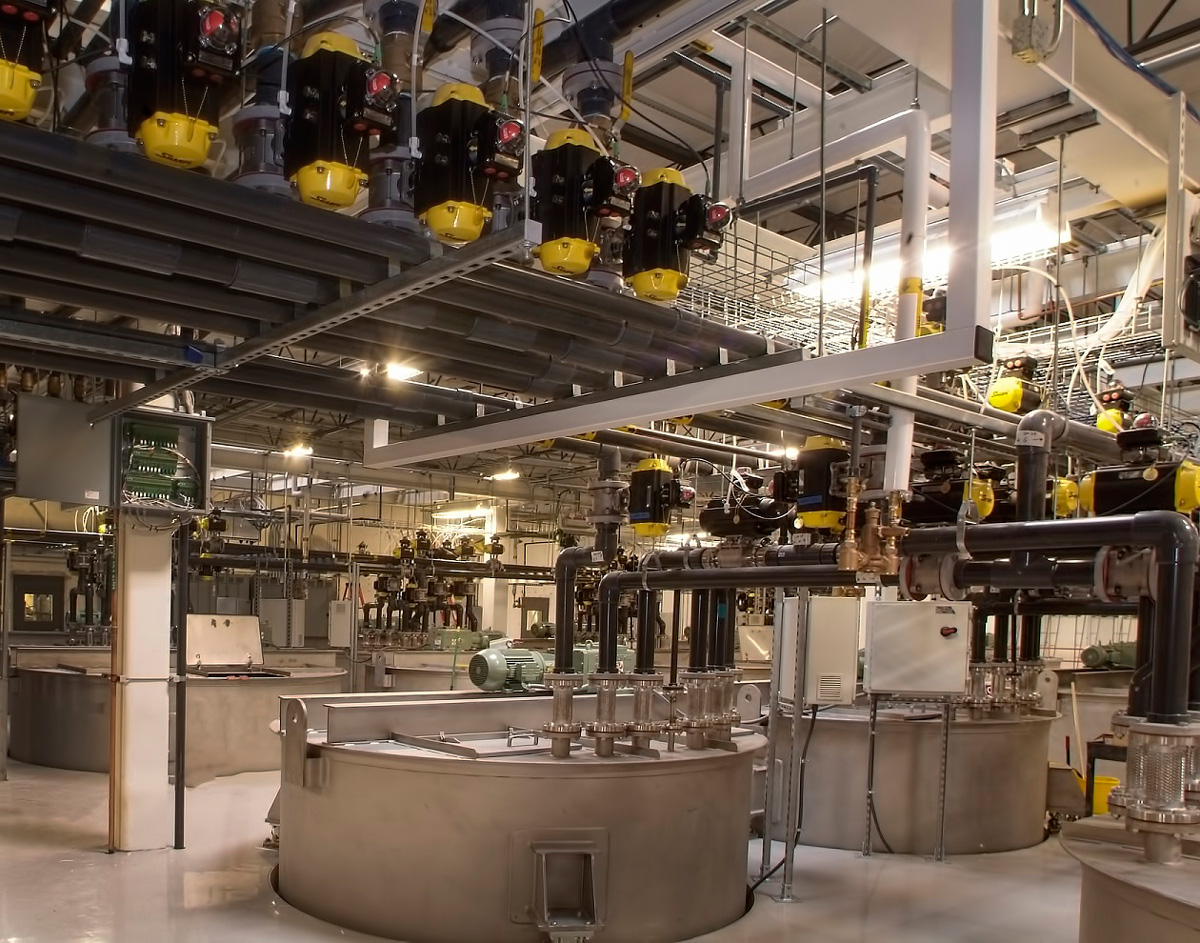

At the end of the implementation of the imposing system of control, supervision and management of their new Phoenix plant, Dunn-Edwards decided not to become autonomous on the platforms and applications deployed by Centris Technologies.

Since 2012, Centris offers Dunn-Edwards a plan of a total of 2,000 hours annually that covers production support, application technical support, anomaly corrections, continuous modifications and improvements and 4 site visits annually lasting one week each.

Four Centris resources remain trained and able to immediately intervene in the event of a problem and develop the new functionalities required by the customer.

With this plan in place, Dunn-Edwards does not have to manage the hiring, training and management of two full-time resources within its employees.

This results in a significant reduction in associated costs and elimination of risk when an employee leaves. In addition, Dunn-Edwards benefits from the growing expertise of the Centris team to make suggestions and improvements to their software applications.

The plan is so win/win that Dunn-Edwards renewed for a fourth consecutive three-year term of PRP.

For some time now, Centris Technologies has been working with Bonduelle North America to support them with their Zénon manufacturing software from Copa-Data.

The Permanent Resource Plan (PRP) with Bonduelle is related to the project to modernize the industrial application mounted on the Zénon platform for the St-Denis-sur-Richelieu and St-Césaire plants.

Centris Technologies will thus complement Bonduelle’s technical team in order to ensure stability of the performance of the software solution deployed as well as rapid support in the event of an anomaly, the goal is that the tool can be an important aid for production teams and management.

The needs of modern production plant operations teams are constantly evolving, this partnership will also allow Bonduelle to have access to our development team in order to keep their state-of-the-art tool in line with their evolving and multi-site needs.

We were at the presentation of the results of the 9th edition of STIQ’s Quebec Industrial Barometer. The study demonstrates more than ever that innovation

Catherine Bouchard, president of Centris Technologies, will give a conference on digital transformation project applications that we have realized. Her conference will demonstrate the complete

Centris Technologies is proud to be a new member of the ADICQ (Association for Development and Innovation in Chemistry in Quebec). Having realized several projects

Centris Technologies team met to celebrate the 15 years of the company. Founded by Michel Kakos and John Moseley, Centris has distinguished itself over the

Contact the Centris team for more details:

Copyright © Centris Technologies – All rights reserved | Privacy Policy

Credit: SQU4D Agency