The results of the 2018 Quebec Industrial Barometer unveiled

We were at the presentation of the results of the 9th edition of STIQ’s Quebec Industrial Barometer. The study demonstrates more than ever that innovation

They trust us

Connected products are growing rapidly in many areas. Concentrate on the product, leave us the responsibility of developing the software driving it (control and data acquisition) and assembly logistics.

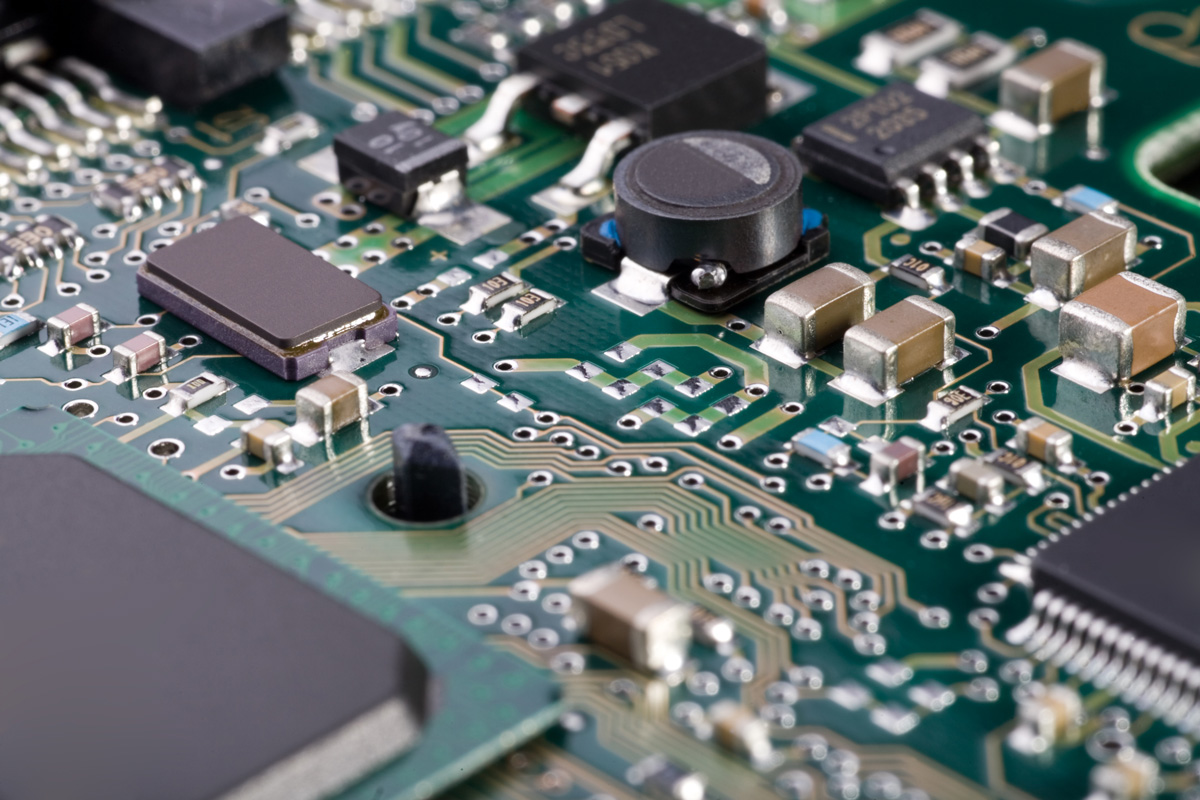

Connected products require a lot of extra effort that manufacturers are not used to managing: the development of electronic platforms to operate the software microcodes that operate the products and, not the least, web and mobile applications to allow users of these products to interact with them.

Centris has developers to support these two software products closely coupled with each other.

In addition, Centris offers logistics services for assembling your products. Within its production facility, Centris can receive all components of your products, program circuit boards, assemble and test everything before packing, sealing and shipping the finished product to your warehouse or directly to your customers.

Essentially, these activities will be removed from your responsibility and taken over by Centris, allowing you to focus on your marketing and marketing activities.

Our range of solutions is vast but always starts with the same step: understand and target your needs.

We work with you to identify your needs and identify which solutions bring real added value to you and your end customers.

We can help you optimize the control applications of your equipment and build software solutions to monitor and acquire data from your various process steps.

Recipe management, quality control, data traceability and productivity and waste monitoring, in an automated and computerised context, are key benefits for any food or beverage producer.

Formula management, control accuracy, process stability and traceability are essential elements for optimized productivity.

Development of embedded software within your equipment as well as application backends to maximize the user experience of your customers. Quality and reliability are key issues.

Complete technology partner for product development and assembly as well as web platform.

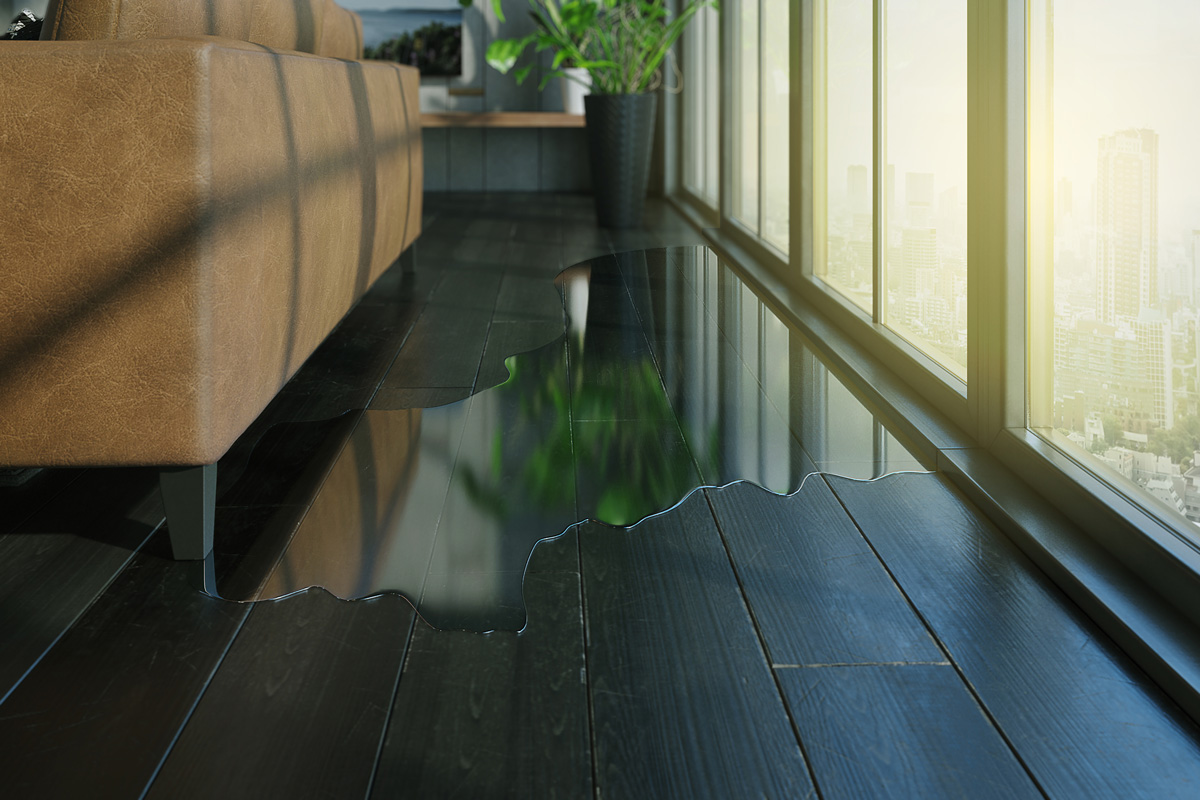

Water-Protec develops and markets a smart product that detects water leaks in residential, commercial or industrial buildings.

When such a leak is detected, the controller closes the main water inlet and notifies the owner through a mobile app and a website.

Water-Protec develops all components of this product – printed circuit, microcode, casing and accessory components.

Water-Protec has a good grasp of the target market and its needs. Their product addresses precisely this sector, but Water-Protec does not have the expertise to develop the printed circuit boards or all the software they offer.

In addition, hiring factory employees to assemble these types of specialty products poses another complex challenge. Centris therefore acts as a software department for Water-Protec in addition to offering its assembly and production logistics services.

Water-Protec doesn’t have to worry about hiring and managing embedded developers, web and back-end programmers, assembly or production technicians.

Eliminating these concerns allows Water-Protec to focus on defining product functions and the important marketing efforts.

Fives group develops huge machining machines for the aeronautics sector.

These machines use hundreds of intelligent engines to position the mechanical supports that will receive the aircraft wings before machining.

These intelligent engines must be integrated into the software designed by Fives group to manage their positioning in real time.

Centris has therefore developed a casing for Fives group that contains a serial protocol converter allowing RS-232 motors to be compatible with the RS-485 standard.

Furthermore, the electric outputs of the engine must be amplified to operate certain engine-related systems. Centris has designed, manufactured and delivered more than 750 units to Fives over several years.

The customer therefore does not have to manage the manufacturing of these boxes and can continue to use the intelligent engines in the context of the delivery of these complex machines.

We were at the presentation of the results of the 9th edition of STIQ’s Quebec Industrial Barometer. The study demonstrates more than ever that innovation

Catherine Bouchard, president of Centris Technologies, will give a conference on digital transformation project applications that we have realized. Her conference will demonstrate the complete

Centris Technologies is proud to be a new member of the ADICQ (Association for Development and Innovation in Chemistry in Quebec). Having realized several projects

Centris Technologies team met to celebrate the 15 years of the company. Founded by Michel Kakos and John Moseley, Centris has distinguished itself over the

Contact the Centris team for more details:

Copyright © Centris Technologies – All rights reserved | Privacy Policy

Credit: SQU4D Agency