Finalist Innovation Award ADRIQ

Centris Technologies is proud to announce that it has been selected as a finalist in the Innovation Award Automation category of ADRIQ (Association of Industrial

They trust us

Centris Technologies has built a solid expertise in the development and integration of custom software solutions, particularly at the level of modern SCADA and MES systems, in order to manage production and extract the maximum information from processes. Furthermore, the deployed solutions can be fully integrated to ensure constant exchanges with ERP enterprise management software packages.

The foundation of the 4th Industrial Revolution is the connectivity of data and objects to each other in order to generate relevant information and provide it to the right people at the right time.

We are here to help you make the digital shift from understanding your needs, developing recommendations and project plans, to developing, deploying and supporting the solution designed for you.

Industrial software solutions generally rely on two major product families: SCADA (Supervisory Control And Data Acquisition) and MES (Manufacturing Execution Systems).

Centris has extensive experience in creating open industrial software solutions built on commercially available platforms such as PcVue, Ignition, Sepasoft and COOX.

Our range of solutions is vast but always starts with the same step: understand and target your needs. It is not a question of following a trend or implementing all the concepts conveyed by the “digital shift”, but rather of identifying what your issue is, what your opportunities are and what solutions will really bring you added value.

We can help you optimize the control applications of your equipment and build software solutions to monitor and acquire data from your various process steps.

Recipe management, quality control, data traceability and productivity and waste monitoring, in an automated and computerised context, are key benefits for any food or beverage producer.

Formula management, control accuracy, process stability and traceability are essential elements for optimized productivity.

Development of embedded software within your equipment as well as application backends to maximize the user experience of your customers. Quality and reliability are key issues.

Specific needs, deep integration of Centris solutions into critical operations in large companies.

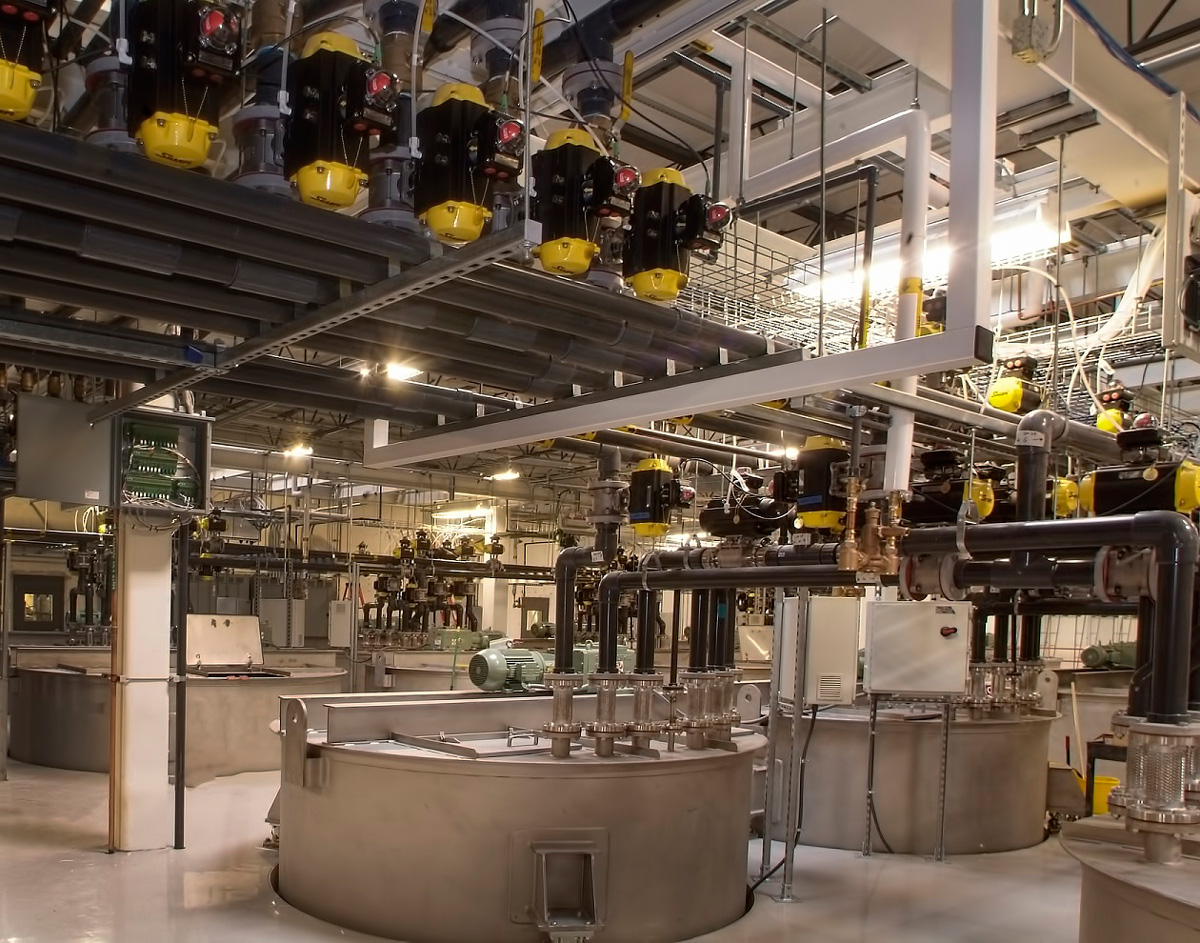

As part of the construction of a new factory that consolidates the entire production of the two old ones, the customer needed an integrated real-time control solution coupled with production operations management functions with ERP integration.

The customer had given himself the mandate to have the most modern factory in the world in that sense.

Centris has developed a SCADA/MES system that covers the entire production operations of the plant. The system manages more than 125 tanks and reactors and executes more than 30 recipes per day.

For the past 10 years, following the system’s start-up, the customer has been implementing nearly 2,000 hours of continuous improvements annually, so that the system evolves at the same pace as the customer.

Before the automation of the new plant, the customer was dealing with a first pass yield of 40%. 6 out of 10 batches had to have some form of rework to meet the strict quality requirements.

Now, less than 5% of the batches have to be reworked. The savings per gallon produced are unequivocal – they produce far more high-quality product, at far less cost.

The system deployed by Centris, as well as the factory, won numerous awards for innovation and operational excellence.

When developing and integrating the new automated production lines at the Longueuil plant, the main integrator needed expertise to integrate the SCADA, which controls all line activities with SAP’s ERP software.

Centris has developed a software type «communication bridge» dedicated to this task by linking by OPC XML the SCADA with SAP using the PI/XI layer.

The communication bridge was developed by adopting a «product» philosophy – essentially, to allow P&W to be 100% autonomous with the use of the software.

The client has been operating the software solution independently for several years with very few support calls to Centris.

The massive data generated by the production lines are all escalated to SAP for logging according to FAA standards.

Centris Technologies is proud to announce that it has been selected as a finalist in the Innovation Award Automation category of ADRIQ (Association of Industrial

We will present the trends and issues represented by the advent of INDUSTRY 4.0 and its impacts on the production floor. You will see an integrated

Centris Technoloiges and PcVue win the “Kinetic Process Innovation Award” for the smart line system deployed at Home Hardware Beauti-Tone Paints in Burford, Ontario. These

Centris Technologies is proud to be the principal sponsor, for a three-year term, of the new Robotics Club at Saint Paul College in Varennes. Anxious

Contact the Centris team for more details:

Copyright © Centris Technologies – All rights reserved | Privacy Policy

Credit: SQU4D Agency